|

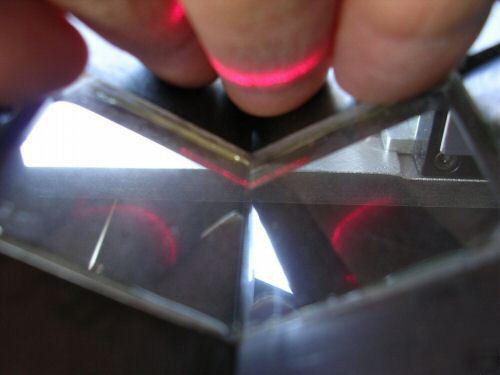

Laser General BT-100 First Article Inspection Gauge For sale- a General Inspection Laser General BT-100 First Article Inspection Gauge. I believe that a sample is pushed forward along the angle iron track and is then scanned with a laser which records its shape and dimensions. The stepper motors to position the sample and the laser would no doubt be coordinated with a computer that of course is not included. Meaning that you will need your own computer, but more importantly, no doubt you will need some proprietary software as well. If you have that, can get your hands on it, or maybe General Inspection can still sell it to you, then I assume this is a bargain price for this type of machine. This Inspection Gauge is NASA surplus, and their condition code indicated it should be functional, but that does not constitute a warranty of any sort. Without a computer to tell it what to do I can’t get it to do much, but the laser does come on when it is plugged in to AC. That is the extent of my testing. Physical condition is excellent, but I cannot say if anything is missing other than the computer which I assume would fit into the cavity just below the inspection level. I don’t see anything obviously broken, but I may well be missing something. I have copied two brief descriptions of this machine from the web. One is from the SAE Aerospace Engineering Online site, which indicated the BT-100 was being exhibited at a conference in October of 1999, so you would have to assume it was a new product or relatively new at that point, otherwise they wouldn’t bother to drag the thing to a conference, would they? From that page- The Laser General BT-100 automatically recognizes OD features and measures them to part print in one pass. External features are measured automatically. Lengths, diameters, radii, tapers, and angles of cylindrical parts are measured simultaneously. SPC packages are integrated into the BT-100. The gage can be used to compare tooling suppliers, headers, and header operators. External features and dimensions are displayed on a terminal screen. I assume these to be accurate descriptions but I certainly am not in a position to check them for mistakes. I leave it up to you to decide if this laser inspection system is suited to your task. You also need to assess whether you have the skills and support to make it work, as I certainly cannot provide any technical expertise. (this posting is the responsibility of the poster) |

b.bright@dfwind.com (Brandi Bright) for more information. All emails will be forwarded to the poster's actual email address.