|

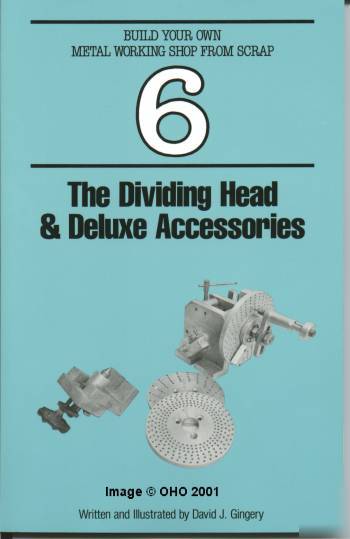

bounce, yer money order will get lost in the mail and yer dog won't come home. click on our "Contact Us" icon above for the quickest response to your questions. LEARN TO DO INDEXING WITH DIVIDING HEAD ON YOUR MILL LEARN TO DO INDEXING WITH DIVIDING HEAD ON YOUR MILL LEARN TO DO INDEXING WITH DIVIDING HEAD ON YOUR MILL LEARN TO DO INDEXING WITH DIVIDING HEAD ON YOUR MILL LEARN TO DO INDEXING WITH DIVIDING HEAD ON YOUR MILL LEARN TO DO INDEXING WITH DIVIDING HEAD ON YOUR MILL LEARN TO DO INDEXING WITH DIVIDING HEAD ON YOUR MILL THE DIVIDING HEAD & DELUXE ACCESSORIES Book 6 The Dividing Head & Deluxe Accessories Now that you have a machine shop you need accessories for the machines. This manual will show you how to tool up your shop to produce the things you want. Making your own tools and accessories is rewarding both in product and pleasure, and it helps greatly to develop your skill. An angle plate, a set screw chuck and an expanding arbor are only the beginning. A clamp dog, threaded mandrels and simple hand reamers are needed in all shops for many operations. Certainly any lathe is improved by a two or four jaw chuck, and a center steady rest for the lathe enables you to do machining operations on the tail end of the stock as well as expanding the capacity of the lathe. Building a worm wheel dividing head will enable you to do precise indexing for gear making and other dividing jobs on your milling machine. This one functions as a rotary table for the drill press too. This is an accessory seldom found in a home shop. You will be amazed at its simplicity, durability and accuracy. Learn basic gear calculations and how to prepare the blanks, index them and mill the tooth spaces. Make your own gear tooth cutters from ordinary lathe tool bits at a fraction of the cost of commercially made gear tooth cutters. Add change gears to the lathe to cut all standard threads from 8 to 80 per inch, both right and left hand and internal or external. A threading indicator is added to the carriage so that you can do accurate threading without reversing the motor to return the carriage after each pass. You'll find that the gear driven fine feeds are much better than the original round belt carriage feed drive on the home built lathe. You won't want to stop here for much more is easily possible. The dividing head not only divides gears but will also do graduated feed collars and protractors. All divisions through 50 and all even numbers and multiples of 5 through 100. Many numbers beyond are available up to 1,960, and you can easily make a special plate for any number of divisions in a special job. Now that you have your own foundry and machine shop you can have any item of equipment you want, and you can build it yourself from scrap materials. Soft cover 5 1 /2" X 8 1 /2" 159 pages. Visit my MarketplaceAdvisor Gallery! Power Tools for Power Sellers! Phone: (***) 744-4449 M-F 9:00 to 4:00 Pacific Standard Time This item has been seen by alt people! (this posting is the responsibility of the poster) |

bernard-reese@dfwind.com (Bernard Reese) for more information. All emails will be forwarded to the poster's actual email address.